S-80

Hay and forage crops are grown on more acres in the United States than any other crop. Three major facts in hay and forage operations present special safety hazards--field terrain, equipment, timing of operations and crop conditions.

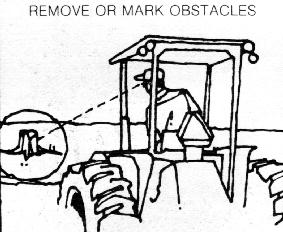

Often hay and forage crops are grown on ground too rough, steep or unsuitable for row crops. This makes field and machine preparations especially important for safe operation. Some steps to help eliminate potential hazards are:

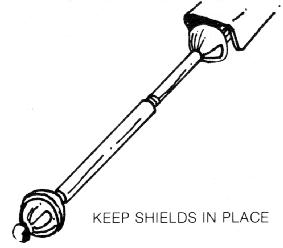

Most hay and forage harvesting machines have several moving components and one or more forms of cutting action. Check your equipment carefully. Know where the hazards are. Keep shields on parts that can be shielded and avoid the others.

Weather and the stage of maturity and moisture content at which a plant is cut and processed are important considerations in forage crops. Often the need to beat bad weather, or to cut the crop at just the right stage can rush operators into disregarding safety. With today's modern equipment, a faster harvest is possible. But the operator must remember safety is more important than speed. Never get in such a rush that you neglect safety precautions.

There is a wide variety of machinery which gets the job done quickly and, with a knowledgeable operator, safely. Each type of machine has unique safety hazards, and special cautions for safe operation.

When considering safe operation of mowers and conditioners, pto safety is vital. Always make sure the machine is hooked up correctly. Never attach a 540 rpm mower or conditioner to a 1000 rpm pto tractor. Operating a mower or conditioner at the wrong speed can cause machine failure and possibly injure you. Be extremely careful when working near pto shafts. Make certain that all safety shields are in place before you operate the mower or conditioner, or any other pto-driven machine. Rotating pto shafts that are not properly shielded are potential killers.

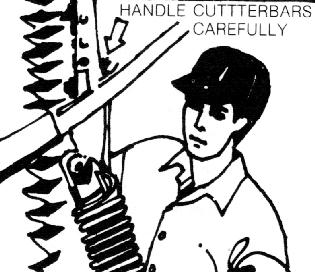

Cutterbar--Even though precautions are taken to insure correct operation of mowers and mower-conditioners, plugging or trash build-up on cutterbars may still occur. To safely unplug the cutterbar or remove trash. follow these steps:

Reels--Most of the safety precautions applying to mowers and cutterbars apply to mower-conditioners. However, in addition, mower-conditioners have reels located over the cutterbar to deliver the crop to the crimping rolls. The reel is an extra reason, in addition to the cutterbar, to shut off the engine and disengage the pto before going near it.

Crimper Rolls--Conditioners and mower-conditioners use crimping or crushing rolls to condition hay so it may dry faster. The conditioning rolls are pto-powered. They pull the hay between them, and throw the hay out the back of the machine. For this reason, never allow anyone to stand near the back of a conditioner, or mower-conditioner during operation. The crimping rolls may pick up a stone or other object, throw it out the back and injure someone. Never work on or around crimping rolls unless the engine is off and the pto disengaged. The rolls can easily grab your hand or clothing if you leave the machine operating. Don't take a chance.

Windrowers save valuable time in haying operations. They can mow, condition and windrow hay in one trip over the field in a similar way to mower-conditioners. But windrowers present two additional safety considerations:

Auger platforms--The auger platform poses potential safety hazards, not only because it is an additional moving part, but also because . may get plugged up by crops. Operators often get careless when unplugging machines. The potential hazard of the auger lies in its shearing and pinching action. The same precautions in unplugging, servicing, repairing and inspecting mower-conditioners should be followed with windrowers. Never work on the platform, including cutterbar, reel or auger, without first disengaging the pto and shutting off the engine.

Windrower speed--Windrower speed is determined by the terrain and the density of the crop. When operating over rough terrain or on hillsides, take care to avoid holes or obstacles that can tip a windrower or throw you from the machine. Crop density also affects the speed at which you operate the windrower. In heavy crops, high operating speeds cause frequent plugging. The more often you must unplug the machine, the higher the chances for an accident. Also, remember that by taking the crop in at the proper speed you'll save time. Frequent stops to clear the machine almost always consume more time than steady harvesting at a slower speed.

Steering mechanisms--Steering mechanisms on windrowers consist of steering levers and a steering wheel. The steering levers are for sharp turns at the end of the field. Adjust speed according to the type of turn to be made. Use the steering wheel to obtain trim and for transport. Make turns on hillsides with care. Reduce speed and make turns with caution to avoid overturning.

Platform height--The height at which you operate the platform will vary from crop to crop. When harvesting hay crops, the platform may be operated very near the ground. Keep a close watch for rocks or other obstacles that could be hit or picked up by the platform. Irregularities in the ground also present safety hazards.

Baling usually puts stress on the operator to get the job done quickly and efficiently. Weather conditions can change rapidly and the value of the crop may be cut by conditions that are too wet, too cool, too hot or too dry.

But, no crop, no matter how large or how good, is worth injury or death. Careless operation that saves time is foolish. Slow down and work steadily.

Rectangular-Type Balers--Balers producing rectangular bales use a pickup head and auger to feed the hay to the bale chamber for compression and bale formation. As the hay enters the bale chamber, two knives slice it and distribute it uniformly in the bale chamber.

These and other components can injure you if you do not take all safety precautions during operation and servicing. Make sure all such parts are completely stopped before you get near them. A baler in good mechanical condition adds to your chances for safe and efficient operation.

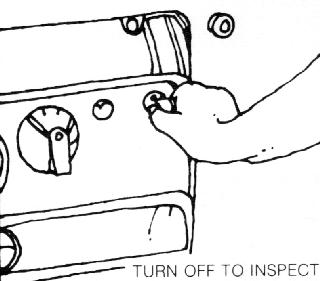

Correct ground speed is important to safe baler operation. If you travel too fast, the baler can become overloaded. If operating over rough terrain, the knotter may miss tying bales if the baler is bouncing too hard. If the need should arise to adjust, inspect, or repair the baler, follow these procedures for your safety:

If you need to test the bale knotter, the proper procedure is to disengage the pto, shut off the tractor engine and then turn the flywheel by hand after tripping the knotter drive. With the flywheel turning slowly, you can observe the knotter going through a tying cycle in slow motion. But, be sure you just watch while the parts are moving. Keep hands away!

Round Balers--Although a different mechanism from the rectangular baler forms the round bales, practice the same safety precautions. Always be sure the pto is disengaged and the engine shut off before dismounting to service or adjust the baler.

Round bales are often left in the field for feeding, but if hauling them, take extra care when stacking and transporting them because they roll easily.

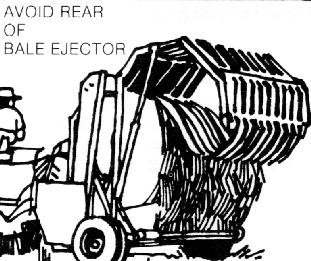

Bale Electors--Three mechanisms for bale ejecting or throwing are:

Never allow anyone to stand behind or work on the ejector while the pto and engine are operating.

Manual bale loading--Manual bale loading can be done safely if it is done carefully. The nature of wagons and bale handling means the operator and bale handlers alike should take extra care. Be sure everyone is aware of these potential hazards:

It is just as important to practice safety while transporting bales. Travel at a safe speed and do not allow riders on top of the hay or on back of the wagon or truck.

Automatic bale handling systems rely heavily on hydraulics and chain conveyors; observe the following safety precautions:

Safety procedures for operating stackers include:

Stack movers use chains or links revolving on beams to load and unload stacks. Hydraulically operated, the conveyor chains are in the open. Do not allow anyone near the mover while it is in operation as they could become entangled in the chains.

Take the same safety precautions with stack movers as with stackers. In addition, place an SMV emblem and proper reflectors on the back of a stack being transported because the tractor's emblem is blocked from view.

Big bale machines form bales weighing from 500 to 2,000 pounds or more. Do not eject large bales on slopes where they may roll away. Because the bale is heavy, once it starts moving it has a tremendous force that can damage fences, other machinery, or injure people.

If you must move a large bale from a slope, be especially careful. Pick the bale up on the lower side of the slope. This will reduce the chances of upsetting your loader and will keep the bale from starting to roll down the slope.

Some suggestions for safe operation of the big-bale balers are:

The large bales may be transported by tractor loaders, 3-point hitch carriers or by trailing bale movers. Proper tractor weighing is important to avoid tipping backwards. Keep everyone clear of the area while loading and transporting the bale. Bales may roll from the front-end loader and crush operator if loader is raised too high.

Both cylinder and flywheel types of forage harvesters may have self-sharpeners. The use of self-sharpeners requires extra precautions from the operator because sharpening is done while parts are moving. You must be aware of these and other potential hazards from different types of crop heads. Except for flail-style harvesters, most forage harvesters are available with different types of pick-up heads:

All pickup attachments and the flail chopper have moving parts which are designed to cut and handle crops. Never approach them while the engine is running. Treat them with care.

Other safety suggestions for forage harvesters include:

Adapted with permission from "Fundamentals of Machine Operation", Deere & Company by F.R. Willsey and David H. Loewer, former staff members in Agricultural Engineering.

For more information, contact Bill Field, Agricultural and Biological Engineering, phone: 317-494-1191 or e-mail: field@ecn.purdue.edu

Cooperative Extension work in Agriculture and Home Economics, state of Indiana, Purdue University, and U.S. Department of Agriculture cooperating; HA. Wadsworth, Director, West Lafayette. IN. Issued in furtherance of the acts of May 8 and June 30, 1914. Purdue University Cooperative Extension Service is an equal opportunity/equal access institution