AE-105

Advantages and Disadvantages of Methane The Methane Generation Process Methane from Animal Waste--Potential and Problems Digester Gas Value and Uses Energy value of the gas Uses for the gas Digester Design and Construction Digester size and environmental requirements Digester construction requirements Digester Gas Collection Storage, Corrosion and Safety Collecting the gas Storing the gas Minimizing odor and corrosion problems Safety considerations Monitoring the Digester Recent Digester Innovations Corn cob digesters Thermophillic digesters Liquid manure-pit digesters Determining the Feasibility of Methane Production Summarizing the Example Results Additional Information on Methane Generation

Methane, which is the principal component of natural gas (95-98 percent), is removed commercially from deposits deep within the earth. This methane was formed millions of years ago in swampy areas (hence it is sometimes called "swamp gas") by the biological conversion of organic matter.

The technology needed to generate methane from livestock waste and other farm refuse has been known for about 100 years. But due to inexpensive and abundant petroleum energy, its use has been limited in the U.S. Today, however, high energy costs and low profit margins experienced in some livestock enterprises as well as recent digester improvements through research are causing many farmers to re-evaluate the feasibility of on-farm production of methane gas from livestock waste.

This publication describes the methane generation process, discusses the design of on-farm systems and their problems, and provides a procedure for determining the potential of developing the technology on your farm.

Advantages. The main one is that a useful end-product, methane gas, is produced. Also, the odor potential of a well digested livestock waste is considerably reduced. Although digested waste has slightly less fertilizer value than nondigested waste, it is more readily available to plants. It is simply converted to a more useful form.

Disadvantages. There are several that must be carefully considered in assessing the potential of on fore-arm methane generation.

* A methane digester is large and expensive. The expense stems from the fact that it must be well-insulated, air-tight and supplied a source of heat. The size of a conventional digester is equal to 15-20 times the daily waste volume produced, or more if the waste is diluted before digestion. The volume of waste that must be disposed of increases accordingly if dilution water is used.

* A very high level of management is required. A methane digester can be extremely sensitive to environmental changes, and a biological upset may take months to correct. Methane generation ceases or is very low during an upset.

* Start-up--usually the most critical phase of methane generation-is difficult. Methane-producing bacteria are very slow-growing, and several weeks are required to establish a large bacterial population.

* Methane is difficult to store, since at normal temperatures the gas can be compressed but not liquefied without special, very expensive equipment.

* Finally, methane can form an explosive mixture if exposed to air.

Methane generation is accomplished by anaerobic digestion (biological oxidation in the absence of oxygen) of organic substances such as livestock waste and plant refuse. The gas produced in an on-farm digester is only about 65 percent methane, the rest being carbon dioxide and trace organic gases.

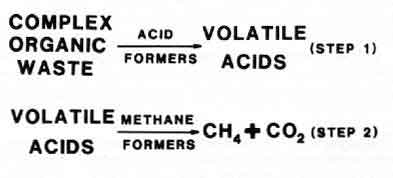

Methane generation requires two main groups of anaerobic bacteria-the `acid formers', which convert waste to organic acids; and the `methane formers', which then convert these organic acids to methane and carbon dioxide (Figure 1). Also, there are two distinct temperature ranges in which these bacteria can produce significant amounts of methane gas-the mesophillic range (90-110F)and the thermophillic range (120-140F). Recent research using thermophillic bacteria shows some promise and will be discussed briefly later; however, this publication deals mainly with conventional digestion units operated in the mesophillic range.

Methane generation is much like the controlled combustion (incomplete burning) of wood to produce charcoal-i.e., burning a substance in an air-limited environment to produce a more readily usable, yet high-energy end-product. The combustion of charcoal requires oxygen to be completed and produces heat, ash, water vapor and carbon dioxide. The combustion of methane also requires oxygen to burn producing heat, water vapor and carbon dioxide.

Production potential. Methane production is usually expressed in terms of cubic feet of gas generated per pound of volatile solids destroyed. Volatile solids are the organic portion of livestock waste; about 80 percent of the manure solids are volatile. A gallon of liquid manure containing 8 percent solids potentially can provide about 3 3/4 cubic feet of digester gas, or 2 1/2 cubic feet of methane (Roughly 10-13 cubic feet of gas can be produced per pound of volatile solids destroyed in a properly-operating digester. Since about half of the volatile solids added can be destroyed and half to three-fourths of the gas produced will be methane, about 5 cubic feet of digester gas (3 cubic feet of methane) can be produced per pound of total manure solids added).

In terms of digester size, it is possible to produce 3/4 to 2 1/2 cubic feet of gas (1/2 to 1 1/2 cubic feet of methane) per cubic foot of digester volume. The gas production expected from various livestock species is shown in Table 1.

Item Dairy Beef Swine

-----------------------------------------------------------

Raw manure (lb.) 82.0 60.0 65.0

Total solids (lb.) 10.4 6.9 6.0

Volatile solids (lb.) 8.6 5.9 4.8

Methane potential (cu.ft.)* 28.4 19.4 18.6

-----------------------------------------------------------

* Based on 65 percent of gas being methane.

Toxic components in waste. Several substances commonly found in livestock waste can inhibit methane production if present in large enough concentrations. The most common is ammonia because it is present in large quantities in animal urine. An ammonia concentration of 1500 parts per million (ppm) is considered the maximum allowable for good methane production (Table 2). Above that level, the waste should be diluted with water.

Concentration

(mg/l of Ammonia-N) Effect

----------------------------------------------

5 - 200 Beneficial

200 - 1000 No adverse effect

1500 - 3000 Possible inhibition at

higher pH Values

Above 3000 Toxic

------------------------------------------------

Certainly, large quantities of antibiotics and cleaning disinfectants should be kept out of the digester. For this reason, consider excluding farrowing building waste from the digester. The antibiotic rumensin is also toxic to methane bacteria and should not be fed to cattle whose waste is to be used for methane generation.

Value of adding crop residues. The primary limitation on livestock waste loading rates is the high nitrogen (N) content compared to its carbon (C) content. The ratio of carbon to nitrogen in that waste added to the digester should be 20 parts C to one part N for optimum methane production.

Crop residues and leaves, which are usually low in nitrogen content but high in carbon, could be useful in improving digester performance. Mixing crop residue with high nitrogen livestock waste provides a more favorable C:N ratio; and gas production should increase accordingly.

If we know the potential for methane production from various livestock species and the cost of comparable amounts of commercial fuel, we can then determine the value of digester gas. Assuming digester gas has an energy value of 650 British Thermal Units (BTUs) per cubic foot and a gallon of propane fuel, with an energy value of 91,700 BTUs, costs 60 cents (1980 price), it takes about 235 cubic feet of digester gas to equal one dollar's worth of propane. Table 3 estimates the value of the potential gas production from each livestock type.

Unfortunately, up to 1% of this gas must be used to heat the manure that is put into the digester. In addition, some heat is needed to keep the digester warm during winter months.

Average Animals needed

animal Value per to equal

Species weight animal $1.00 per day

----------------------------------------------------

lb. cents/day no.

Dairy cattle 1300 17 6

Beef cattle 900 9 11

Swine 150 1.3 77

----------------------------------------------------

*These calculated values are based on the methane production

assumptions outlined in the text, using 1% of the methane to maintain

digester temperature and a value of 60 cents/gal. for propane (1980

price).

Digester gas can be used wherever natural gas is applicable. Digester gas requirements for household activities were computed at Pennsylvania State University (Table 4). On the farm, it can be used for grain dryers or to operate gas water heaters, which provide heat back to the digester and floor heat for nearby livestock buildings. It can also be burned in a commercial space heater.

Household use Gas volume needed

-------------------------------------------

Cooking 20-25 cu.ft./hr. per burner, or

150-300 cu.ft/day

Heating 165 cu.ft./hr. per 100,000 BTU/hr.

input

Lighting 2-3 cu.ft./hr. per mantle

-------------------------------------------

Its greatest potential is as a heating fuel. The equipment needed for heating is nearly identical to that required by natural gas, except that the gas ports and air supply must be modified to ensure proper combustion. Natural gas burners need some modifications, since the flame from burning digester gas tends to `lift' from the burner. Therefore, a certain amount of trial and error is required, and the holes in the burner mantle will probably have to be enlarged somewhat.

Engine-driven devices are not very efficient when operated directly from a methane generator. For example, an electric generator (driven by a gas engine) operating at variable torque has a poor efficiency, because the hourly gas production and consumption are nearly the same, regardless of the amount of loading on the system. About 16-18 cubic feet of digester gas are required per horsepower-hour, assuming an energy value of 650 BTU's per cubic foot.

Engine efficiency can be improved by removing carbon dioxide from the digester gas before combustion, then burning the remaining methane. Digester gas can also be injected into the air stream in a stationary diesel engine. Up to 90 percent of the fuel entering an engine by this technique can be methane gas.

One potential use for digester gas just now receiving attention is as a heat source to operate an on fore-arm alcohol production plant. Some producers are experimenting with a system of fermenting corn to alcohol that includes feeding the `stillage grain' byproduct to livestock, using livestock manure to generate methane, then using the methane directly to fuel the alcohol production process.

With current alcohol production technology, an energy equivalent of about 30 cubic feet of digester gas is required to liquefy and ferment the grain to produce one gallon of ethanol, and another 60 cubic feet of digester gas per gallon of alcohol for distillation to 160-180 proof quality. This equals about one gallon of alcohol for every five beef feeders, whereas the stillage from a gallon of alcohol can provide feed for about three beef feeders.

Digester size depends on the amount of waste to be digested and the amount of dilution required. Recommended loading rates vary with animal species and with how the waste is handled. For example, if the urine (which contains about two-thirds of the ammonia) is excluded from the waste, loading can be correspondingly greater. Table 5 shows the digester volume needed and other digester design values for each livestock type.

Item Dairy Beef Swine

--------------------------------------------------------------------------------------------------

Manure: water dilution ratio 1:0 (undil.) 1:0.92 1:2.2

Amount of dilution water per 1000 lb. of animal weight 0 gal. 7.0 gal. 18.0 gal.

Detention time 15 days 15 days 12.5 days

Digester volume per 1000 lb. of animal weight 20.6 cu.ft. 28.8 cu.ft. 43.4 cu.ft.

Estimated gas per 1000 lb. of animal weight 43.7 cu.ft. 29.8 cu.ft. 28.6 cu.ft.

Estimated methane production per 1000 lb. of animal weight 28.4 cu.ft. 19.4 cu.ft. 18.6 cu.ft.

Estimated daily methane production per cu.ft. of

digester volume 1.4 cu.ft. 0.67 cu.ft. 0.43 cu.ft.

---------------------------------------------------------------------------------------------------

* From MWPS-19, "Livestock waste Management with Pollution Control."

Start-up can be speeded by providing a source of methane bacteria. One way of doing this is to initially fill 20-25 percent of the digester volume with active waste digester sludge from a municipal sewage plant, then to gradually increase the amount of livestock waste added at each loading over a 6-8 week period until the system is fully operational.

Optimum conditions for digester operation are: uniform loading (preferably daily), neutral acidity, 95F temperature, a 20:1 carbon/nitrogen ratio and levels of harmful substances below their inhibiting limits. A near-neutral acidity (pH=7.0) is a good indicator of proper operation. This means that the bacterial populations are in balance, with the `acid formers' producing only as much organic acids as the `methane formers' can use.

Less-than-optimum environmental conditions can cause a digester upset, usually resulting in acid conditions. This is because acid-forming bacteria will thrive under a much wider range of environmental conditions than the slower-growing methane-forming bacteria.

Acid conditions can be temporarily controlled by adding an alkaline substance such as lime. However, the original cause of the imbalance must be found and corrected if gas production is to be maintained.

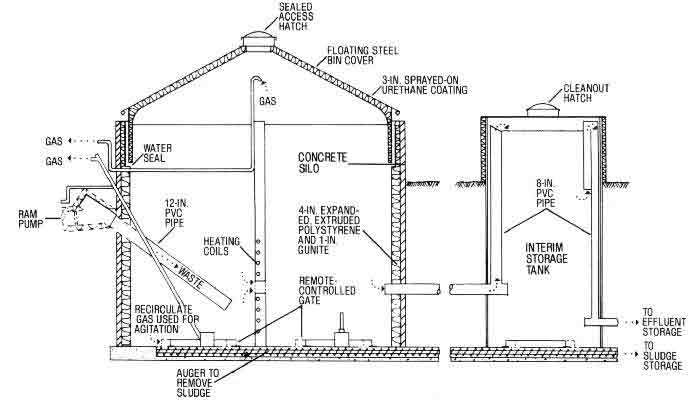

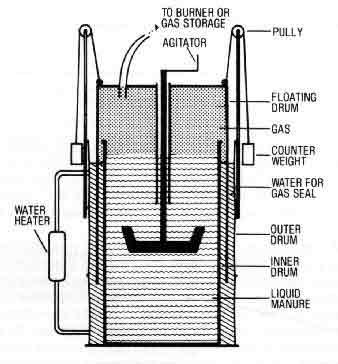

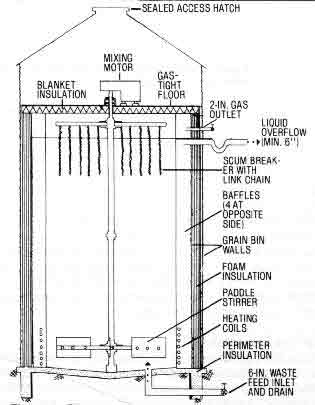

Digesters must be airtight and must be constructed so that they can be insulated, heated and the contents stirred. The digesters shown in Figures 2-5 are not necessarily the best possible designs, but are some that have been successfully used or proposed for use by knowledgeable individuals.

Insulating. Because temperature is critical to methane generation, heat conservation in the digester is essential. To utilize the insulating properties of the soil, consider mounding the soil up around the tank or burying the tank in a well-drained site so that the soil's full insulating potential can be realized (Figure 2).

Insulate the digester surface to a level of at least R=10 where it is in contact with the ground and to at least R=20 where it is in contact with air (R is a measure of a material's ability to resist the flow of heat. The higher the R value, the better the insulation value). See Purdue Extension Publication AE-95, "Insulating Livestock and Other Farm Buildings," for information on selecting and installing insulation.

Heating. The system most commonly used to provide a year-round 95F temperature for methane generation is a heat exchanger where hot water pipes are placed within the digester. The water can be heated outside the digester, possibly using a methane-fired water heater.

For best results, waste should be preheated before adding it to the digester. As much as five times more heat may be needed for the preheating process as for maintaining digester temperature.

Stirring. Mixing is important to ensure adequate contact between the bacteria and the waste and also to help strip gas out of the liquid. Mixing can be done using either: (1) a mechanical mixer, (2) a compressor to bubble collected gas back through the digester liquid or (3) a closed-circuit manure pump.

A mechanical stirrer works well as long as a good air seal is maintained. Atmospheric oxygen must be excluded from the digester, to eliminate the threat of explosion. One method of doing this is with a floating cover, as illustrated in Figures 2 and 3.

If a compressor is used for mixing, piping can be inserted into the digester, and recirculated gas from a storage unit injected by means of an open pipe or diffuser at the bottom of the tank. This creates turbulence and keeps the solids in suspension.

To facilitate the manure pump method of stirring, set piping when the digester is constructed. Either a diaphragm or trash pump located outside the digester should work well for this purpose.

For the mechanical or pump-type methods, to determine the horsepower (hp) needed to mix the digester contents, use the equation:

hp=0.185 x % total solids x liquid capacity (in 1000 cu.ft. units).

For example, a 10,000-cubic foot digester containing waste at 6 percent solids would require a 11.1 hp mixer (0.185 X 6% X 10). As to frequency of stirring, some small-scale studies indicate that intermittent stirring (3-4 times per day) is about as effective as continuous stirring.

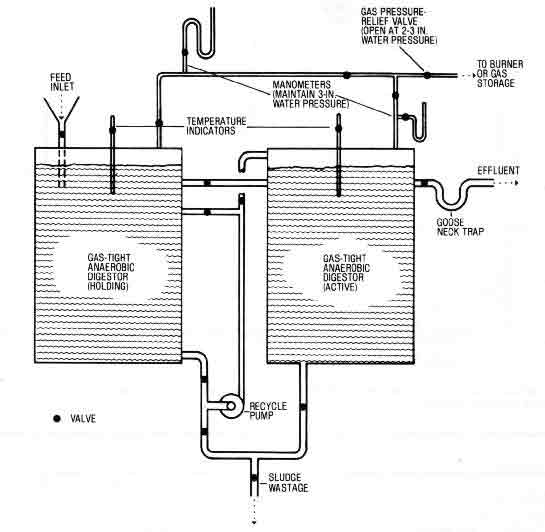

As stated earlier, digester gas is usually 60-70 percent methane, with the rest being carbon dioxide, some hydrogen sulfide and other trace gases. To insure against contamination with atmospheric oxygen a positive static pressure of at least 3 inches water should be maintained over the liquid in the digester and gas collection systems.

This can be done by collecting gas using either (1) a floating cover on top of the digester or (2) a pressure regulator to release gas from the digester after a certain pressure level has been reached. In the case of the former, the cover `floats' on the compressed gas above the liquid. Some gas storage occurs under the cover, and the weight of the cover provides a positive pressure for gas distribution.

Any gas piping used should either slope back to the digester or have condensate traps to prevent water vapor from condensing and blocking the lines when the gas cools. Also, it is important that a gas meter be installed on the gas collection line in order to monitor digester operation; a high, stable gas production level usually indicates good operation.

Gas storage vessels should be designed with variable volumes, because they must adjust for differences in the rate of gas production and consumption while maintaining uniform pressure. Of course, the most practical way of minimizing costly gas storage is to find uses for the gas which parallel its production rate.

A floating digester cover can be used for gas storage as well as for gas collection. This is simply a pontoon cover which floats on the liquid surface and has skirt plates extending down into the liquid to provide a seal (see Figure 3). The weight of the floating cover provides a pressure head and allows the gas to be withdrawn as it is needed.

A high-pressure gas storage unit is possible but quite expensive for on-farm use. It can be either cylindrical or spherical in shape and of welded-steel construction. Since there is a danger of explosion or leakage with pressurized storage, consult a knowledgeable engineer and metal working shop for help. Medium-pressure storage (less than 100 psi) is more feasible for on-farm use than high-pressure storage.

Some pressurization increases the amount of energy that can be stored (Table 6). But it is impractical to liquefy methane on the farm, since 700 pounds per square inch (psi) pressure and -150F are required to do it.

BTUs per BTUs per

Pressure cubic foot gallon

------------------------------------

15 psi 650 87

30 psi 1300 170

45 psi 1950 260

60 psi 2600 350

75 psi 3250 435

90 psi 3900 520

------------------------------------

Hydrogen sulfide, which has a rotten egg smell, could be produced if the waste contains large amounts of sulfates. In general, however, the gas from a properly-operating digester should have only a slight odor, because both major components--methane and carbon dioxide--are odorless. In any case, the gas produced is stored in an airtight container and burned, thus eliminating any odor problems.

Corrosion is another matter. It can be severe. Therefore, the gas should probably be passed through a filter containing lead filings or a mixture of woodchips and iron oxide to remove any hydrogen sulfide. "Sorb beads" manufactured by Mobil Oil can also be used to remove hydrogen sulfide and water vapor.

For removal of water vapor alone, consider using a condenser. And to remove carbon dioxide, use a molecular sieve.

Methane is extremely explosive when mixed with air at the proportions of 6-15 percent methane. Digester gas is heavier than air and settles to the ground, displacing oxygen. If hydrogen sulfide is present, the digester gas can be a deadly poison.

Always vent the open side of manometers (static pressure gauges) and pressure relief valves to the outside, and provide plenty of ventilation if the digester is located indoors. Be careful when compressing and storing digester gas. Special equipment and special tanks must be used if the gas is stored at high pressures.

Fortunately, unlike that added to municipal sewage digesters, livestock waste is fairly uniform in composition. Once the process has started and reached steady state, upsets are not too common if the digester is properly managed. Monitoring digester operation, nevertheless, is a good idea and can be accomplished fairly easily, using gas production or pH of the digester liquid as an indicator.

Gas production. This is the simplest and most reliable indicator. In a batch-loaded digester (one in which waste is added every month or so), if gas production drops off gradually, the food supply available to the bacteria is probably depleted, indicating it's time to add more waste to the digester. If gas production drops off rapidly (within 1 or 2 days), the reason is probably an upset digester. Among the potential causes, the major ones are: too high a level of toxic compounds in the waste feed, too high a feed rate or too cold a temperature in the digester.

A low digester temperature could be the result of a failure in the heating system. If a large amount of waste is added at one time, it should be preheated to 95F to prevent thermal shock to the methane bacteria. Better performance is usually obtained with continuous loading-i.e., where the digester is loaded with smaller amounts of waste on a daily basis.

pH level. The pH (level of acidity or alkalinity) can be measured easily by inserting pH paper into the digester liquid and comparing the resulting color intensity that develops with a color chart. The pH should be as close to 7.0 (neutral) as possible. A pH below 6.0 indicates a digester upset. You can purchase pH paper from most drug stores, aquarium shops or wine supply stores.

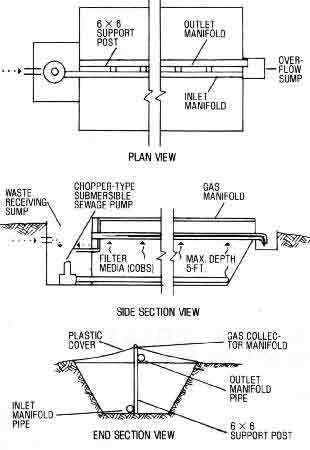

A laboratory study at Purdue University found that an anaerobic digester containing corn cobs can be used to treat swine waste and produce methane at temperatures as low as 65F (Figure 6). The study used a detention time of 5 days and a loading rate of 7.5 pounds of volatile solids per cubic foot per day. This system holds a great deal of promise for on farm use, with daily gas production as high as 1.5 volumes of gas per volume of digester.

Since the cobs are high in carbon but low in nitrogen, they improve the C:N ratio by supplying additional organic carbon. They also provide a support medium onto which bacteria can attach and be retained within the digester instead of being removed with the digester effluent.

Thermophillic (high-temperature) digesters have been designed that operate satisfactorily at a 5-day detention time and a solids level of 10-20 percent. Digester gas production has been around 11 cubic feet per pound of volatile solids destroyed. Operation is normally started by bringing the digester up to a temperature of 130F at a rate of about 3F per week.

In many ways, thermophillic digestion is better than digestion at 950F. Gas production is about 20 percent higher and solids breakdown about 10 percent higher. In addition, the higher temperature kills more pathogenic bacteria, thus allowing the digested waste to be used as a feed supplement without further sterilization.

But thermophillic bacteria digestion also has its disadvantages. The methane content of the gas is somewhat lower (55 percent), and digester operation is not quite as stable as conventional digesters.

The main drawback, however, is the high temperature required. Roughly twice as much heat is needed as for conventional digesters. Thus, the digester must be well-insulated (R=20 for digester surfaces in contact with the ground and R=30+ it exposed to the atmosphere). In addition, the digester should be stirred to insure good contact between bacteria and organic matter and to maximize gas production.

With the low detention time and high temperatures, some means of reclaiming the heat lost in the digester effluent is necessary to make the system economical. A considerable amount of laboratory and pilot plant testing is currently being done to determine the feasibility of thermophillic digesters.

Researchers at the University of Florida studied an above-ground liquid manure storage structure which was modified for use as a methane digester. The study employed a large, covered storage tank, with waste additions made daily. Gas production was about 60 percent of that in a conventional digester. From this and related work, the following suggestions are offered concerning manure-pit digesters:

* The tank must be seeded initially with bacteria from an active anaerobic digester at a level of 10-20 percent of the tank volume to provide sufficient methane bacteria.

* A seed-to-waste feed ratio on a dry weight basis of at least 20:1 is needed for dairy manure. In other words, it 1000 gallons of liquid dairy manure are normally added each day, the storage tank should initially be filled with about 20,000 gallons of digester sludge. After the tank becomes full, it is pumped down to the 20,000-gallon level and operation begun again.

If municipal sludge is used as seed, a volume ratio of 40:1 is required because the solids content of digester sludge from a municipal sewage treatment plant is about half that of dairy manure.

* Temperature control in this type of digester is not critical as long as the temperature is between 70F and 95F. Digestion is possible at 70F because bacteria are not removed from the effluent and the large numbers of bacteria offset the reduced biological activity at the low temperature.

* The manure storage tank should have a capacity for 180 days storage, because it takes about 100 days for gas production to achieve a steady rate. A floating, gas-tight cover should be used to capture the gas as it is released from the liquid manure.

* When the temperature of the digester liquid goes below 70F, gas production is very low and operation is likely to be unstable. Therefore, heating and insulation are needed in the winter if the digester is to be a reliable source of energy.

Because of the very large volume of heated liquid required compared to a conventional digester, it seems at this point that the manure-pit digester will only be practical in the southern parts of the U.S. Certainly anyone considering converting a manure tank to this system should check with their county Extension office for the latest research information and management recommendations.

The economics of methane production are generally considered questionable, even at today's escalating fuel prices. But energy costs and availability tomorrow could change that feasibility drastically. The following example, while by no means a complete economic analysis, should provide the farmer with a rough idea of the value of methane generation on his farm.

Example: A farmer with a 100-cow dairy herd wants to know if he can economically justify a methane digester. Average cow weight is 1300 pounds. Manure from calves, heifers and dry cows will not be available for use in the digester.

Our Your

Items and calculations example value

------------------------------------------------------------------------------------------------

A. Determine potential volume of gas produced per day. 43.7 cu.ft/

1. Gas produced per 1000 lb. of animal weight (from Table 5). = 1000lb. __________

2. Gas produced per animal per day.

Avg. wt./hd. x Step A.1

(1300 lb. x 43.7 cu.ft./1000 lb.) = 56.8 cu.ft./hd __________

3. Total gas produced per day.

No. animals x Step A.2

(100 hd. x 56.8 cu.ft./hd.) = 5680 cu.ft __________

4. Methane produced per 1000 lb. of animal

weight (from Table 5). = 28.4 cu.ft/ __________

1000 lb.

5. Methane produced per animal per day.

Avg. wt./hd. x Step A.4 = 36.9 cu.ft __________

(1300 lb. x 28.4 cu.ft./1000 lb.)

6. Total methane produced per day. = 3690 cu.ft. __________

No. animals x Step A.5

(100 hd. x 36.9 cu.ft./hd.)

B. Determine amount and value of energy produced.

1. Energy value per day. (Assumes 1/4 of the methane must

be recycled to provide heat for the digester, energy

value of the remaining 75% is 950 BTU/cu.ft., and a gallon

of propane has an energy value of 91,700 BTU

and costs 60 cents.)

Energy value of methane x usable methane x Step A.6 2,630,000

(950 BTU/cu.ft. x 75% x 3690 cu.ft./day) = BTU/day __________

2. Propane equivalent of heat produced.

Step B.1 / BTU/gal. propane

(2.63 mil. BTU/day / 91,700 BTU/gal.) = 28.7 gal. __________

3. Dollar value of energy produced per day.

Price of propane x Step B.2

($0.60/gal. x 28.7 gal.) = $17.22/day __________

4. Dollar value of energy produced per year.

Days/yr. x Step B.3

(365 days x $17.22/day) = $6285.30 __________

C.Determine digester tank volume and dimensions

1. Design liquid volume in the digester (from Table 5)

Digester volume/1000 lb. animal wt. x wt./hd. x no. hd.

(20.6 cu.ft./1000 lb. x 1300 lb. x 100 hd.) = 2678 cu.ft _________

2. Total digester volume (including 1/2 day's storage

for gas produced) in cubic feet.

Step C.1 + (1/2 day x Step A.3)

(2678 cu.ft. + (1/2 day x 5680 cu. ft/day)) = 5518 cu.ft _________

3. Total digester volume in gallons.

Gals./cu.ft. x Step 0.2

(7.5 gal./cu. ft. x 5518 cu.ft.) = 41,385 gal. _________

4. Tank height. (Use 14 foot high digester for this example.) = 14 ft _________

5. Diameter of circular tank for height chosen.

((Step C.2 / Step C.4) x 1.27)1/2

((5518 cu.ft x 14 ft) x 1.27)1/2 = 24 ft _________

D. Determine digester cost, including insulation, heater and mixer.

1. Cost of digester, including tank cover and pump. (Assume a cost of

50 cents per gallon.)

Cost/gal. x Step C.3

($0.50/gal. x 41,385 gal.) = $20,692 _________

2. Cost for digester insulation on cover and sidewalls.

a.Insulation covering. [One way to insulate is to construct a larger

diameter tank around the digester and insulate the space between.

The outer tank does not need to be as watertight or sturdy as the inner

tank. Assume cost of the exterior tank is 1/2 the digester tank.)

Step D.1 x 1/2

($20,692 x 1/2) = $10,346 _________

b. Digester sidewall surface area.

Step C.4 x Step C.5 X 3.14

(14 ft x 24 ft x 3.14) = 1055 sq.ft. _________

c. Digester cover area.

(Step C.5)2 x 0.79

(24 ft x 24 ft x O.79) = 455 sq.ft. _________

d. Total digester surface area.

Step D.2.b + Step D.2.c

(1055 sq.ft + 455 sq.ft) = 1510 sq.ft _________

e. Insulation cost. (Assume $1 per square foot of insulation installed.

Because this cost is extremely variable, check with local builders

when evaluating a digester for your situation.)

Insulating cost/sq.ft. x Step D.2.d

($1/sq.ft x 1510 sq.ft) = $1510 _________

3. Cost of the water heater.

a. Heater sized to supply 30 BTU per hour per cubic foot of digester

liquid volume.

Heater capacity/cu.ft. x Step 0.1

(30 BTU/hr/cu.ft x 2678 cu.ft.) = 80,340 BTU/hr. _________

b. Heater cost. (1980 price for this size heater

with water pipe is about $1000) = $1000 __________

4. Digester mixer cost.

a. Mixer sized to stir digester contents having about

10 percent solids (see Table 1).

Step C.1/1000 x pct. solids x 0.185

(2678 cu.ft./1000 x 10% x 0.185) = 5 hp _________

b. Mixer cost. (Assume a 3-in. diaphragm pump and piping system to

recirculate digester contents, costing about $2500.) = $2500 _________

5. Total digester cost.

Steps D.1 + D.2.a + D.2.e + D.3.b + D.4.b

($20,692 + $10,346 + $1510 + $1000 + $2500) = $36,048 _________

E. Determine the cost of holding digester effluent until spread.

1. Manure produced per day in pounds (from Table 1).

Manure/1000 lb. animal wt./day x avg. wt./hd. x no. hd.

(82 lb./1000 lb./day x 1300 lb. x 100 hd.) = 10,660 lb./day _________

2. Manure produced per day in cubic feet.

Step E.1 / lb./cu.ft.

(10,660 lb./day 60 lb./cu.ft) = 178 cu.ft./day _________

3. Storage volume needed for 180-day capacity in cubic feet.

Days capacity x Step E.2

(180 days x 178 cu.ft./day) = 32,040 cu.ft. _________

4. Storage volume needed for 180-day capacity in gallons.

Gals./cu.ft. x Step E.3

(7.5 gal./cu.ft. x 32,040 cu.ft.) = 240,300 gal./ _________

5. Cost for a prefabricated storage structure. [Assume 15 cents per gallon.)

Construction cost/gal. x Step E.4

($0.15/gal. x 240,300 gal.) = $36,045 _________

6. Cost for an earthen storage structure. (Assume 5 cents per cubic foot.)

Construction cost/gal. x Step E.3

($0.05/cu.ft. x 32,040 cu.ft.) = $1602 __________

Note. It is questionable whether cost of the manure storage unit

should be charged to the digester, since many dairy farms already have

one or will require one whether or not a digester is used.

F. Determine cost of a gas storage unit.

A gas storage unit must also be constructed or else

a use developed which consumes gas at the rate it is produced.

For this example, assume no gas storage is needed. = 0 __________

G. Determine total cost of this methane generation system.

1. Total cost with a prefabricated storage.

Step D.5 + Step E.5

($36,048 + $36,045) = $72,093 ___________

2. Total cost with an earthen storage.

Step D.5 + Step E.6

($36,048 + $1602) = $37,650 ___________

H. Determine the economic feasibility. [The dollar value of methane produced

in Step B.4 can be used to determine the payback period. Table 7 also

assists in determining how much capital can be justified for digester

construction.)

1. Capital investment per head that can be paid back in 7 years

[from Table 7 at 15 percent interest rate and 60 cents per

gallon energy value]. = $285/hd ___________

2. Total breakeven investment.

Step H.1 x no. hd.

($285/hd. x 100 hd.) = $28,500 ___________

--------------------------------------------------------------------------------------------------

Under the best digester operating conditions at 15 percent interest, the break-even point for construction of the earthen holding pit ($37,650) will not be reached in less than 7 years based on Table 7. Current tax credits and government demonstration grants could shorten the pay-back period somewhat.

Per-head investment at a propane equivalent price

and interest rate of-

---------------------------------------------------

$ .60/gal. $ .90/gal. $1.20/gal.

--------- -------- --------

Species 10% 15% 10% 15% 10% 15%

-------------------------------------------------------------------

Dairy $330 $285 $495 $427 $660 $570

Beef 184 161 276 242 368 222

Swine 26 21 38 32 52 42

-------------------------------------------------------------------

* The investment price is based on a 7 year pay-back with 4 percent

of the initial investment allocated to repairs, insurance and

taxes. There is no profit or return to labor included in these

figures, nor are any tax incentives considered. Current tax laws are

in a state of flux. At present, if the methane is used on the farm,

only investment tax credit applies, while digesters which produce gas

for off-farm sale can receive investment tax credit as well as $3 per

5.8 million BTU sold.

It may also be argued that less gas must be diverted for heat during warm months. But this is offset somewhat by the fact that our estimates for gas production are based on ideal conditions, and that all labor costs and profits were ignored. It therefore appears to be uneconomical to construct a digester in our example. (Methane generation will be more attractive for large livestock production units, which have the potential tor considerable `economy of scale' saving.)

Table 7 was prepared to aid you in considering the effect of changing interest rates and fuel prices. This table presents the maximum initial investment that could be made if you expected to pay for the digester in 7 years.

The promoters of commercial anaerobic digesters sometimes add on other economic returns in order to balance larger investments. One example is to give the digested sludge a value as either a feed or a fertilizer. The feed value of sludge is reported to be as high as $100 per ton of dried digester solids (1980 price). Some proponents claim that the feed value is as much as ten times greater than the value of the gas produced. At present, however, few Indiana farmers are willing or able to feed the digester effluent to their livestock.

Another technique is to credit the digester with the fertilizer value of the livestock waste. This fertilizer value is about 1 cent per gallon of digester effluent (1980 price), which works out to 1.5 times the fuel value of the methane. It should be noted, however, that the fertilizer value will be present even if the waste is not passed through a digester, making this credit rather questionable.

In addition, all digesters require some management and labor to control the process. Successful operation for a typical on-farm digester will require a minimum of 1-2 hours per day for monitoring, loading, unloading and performing general maintenance-some systems even more!

Several private organizations and individuals have written about the principle and practice of methane generation. The following list should be useful to those desiring more information.

1. Ram Bux Singh, "Bio-Gas Plant-Generating Methane from Organic Wastes." 70 pages. Available for $6.00 from the Gobar Gas Research Station, Ajitmal (Etawah) Upper Pradesh, India.

2. Les Auerbach, William Olkowski and Ben Katz, "Manual on Home Methane Generation." Available for $5.00 from Les Auerbach, 242 Copse Road, Madison, Connecticut 06442.

3. "Livestock Waste Management with Pollution Control." MWPS-19. North Central Regional Research Publication 222. June, 1975. Write Midwest Plan Service, Agricultural Engineering Department, Iowa State University, Ames, IA 50011, regarding availability and cost.

4. R. Douglas Kreis. "Recovery of By-Products from Animal Waste." A Literature Review, EPA-600/2-79-142, August 1979, National Technical Information Service, Springfield, VA 22161.

The authors wish to express their appreciation to David H. Bache and George F. Patrick of the Agricultural Economics Department Purdue University tor their review and suggestions in the economic aspects of this publication.

New 9/80

Cooperative Extension work in Agriculture and Home Economics, state of Indiana, Purdue University, and U.S. Department of Agriculture cooperating; HA. Wadsworth, Director, West Lafayette. IN. Issued in furtherance of the acts of May 8 and June 30, 1914. Purdue University Cooperative Extension Service is an equal opportunity/equal access institution.