Advantages and Disadvantages of Natural Ventilation... Advantages Disadvantages Where to Use Natural Ventilation Principles of Natural Ventilation Building Location Considerations Building orientation Separation distance Sizing and Design of Ventilation Openings Sizing openings for winter Sizing openings for summer Ridge vent design Eave vent design Sidewall vent design Other Considerations in System Design Management and Operation of Natural Systems Automatic or manual vent control Sample ventilation adjustment scheme Monoslope building ventilation management Draft control Summary Related publications

Most livestock producers are aware of the importance and benefits of a good ventilation system for removing excess moisture and heat and for improving the building environment in general. So the question is not whether there is merit in good ventilation, but how to obtain it.

There are two methods of ventilating livestock housing--mechanical (fan) and natural (gravity or non-mechanical). This publication will deal with natural ventilation, its advantages and drawbacks, where it can be used, principles that operate in a natural system, and finally, basic considerations in the design and management of such a system. (For information on mechanical ventilation systems, see Purdue Extension Publication AE-96.)

Here are the main benefits and drawbacks of natural ventilation to help you determine its potential under your particular situation.

Energy: Natural ventilation does not require energy to operate fans or a furnace, which means fuel conservation and cost savings. If we assume that 35 percent of Indiana's hogs are finished in confinement, the difference in fixed and operating costs between mechanically- (environmentally-controlled) and naturally-ventilated swine finishing buildings would exceed $500,000 annually. If we included gestation buildings, the figure would be even higher. Yet the difference in performance of hogs raised in mechanically- vs. naturally-ventilated structures has not been shown to be significant.

Animal safety: Because natural ventilation systems do not require fans, confinement animals would not be affected by electrical power failures. Over the past several years, the value of swine suffocated in environmentally-controlled buildings due to power failures is in the tens of thousands of dollars.

Lack of control: Probably the most serious drawback of a natural system is the lack of precise control of air flow, which only fan ventilation can insure. Natural ventilation depends somewhat on the difference between inside and outside temperature but mostly on the wind, which can change in both speed and direction every few minutes. This means a building runs the risk of underventilation on calm, hot days and overventilation on cold days.

Building location: Because natural ventilation depends largely on prevailing wind currents, a location where wind would be deflected or blocked is unacceptable for a natural system, although it might be ideal from the standpoint of feed and animal handling.

Difficult-to-correct problems: Good natural ventilation in a livestock building is the result of the `right' design, `right' location and `right' construction. Therefore, a naturally-ventilated building which does not function properly is often difficult and expensive to correct. Sometimes the only solution is to revert to mechanical ventilation.

Naturally-ventilated buildings are most satisfactory for large animals, such as beef and dairy animals over 700 pounds and swine over 75 pounds. Usually, younger animals require higher temperatures in winter and more precise environmental control than can be supplied by a natural ventilation system. A possible exception is small animals on a bedded floor where the bedding provides sufficient protection from the cold.

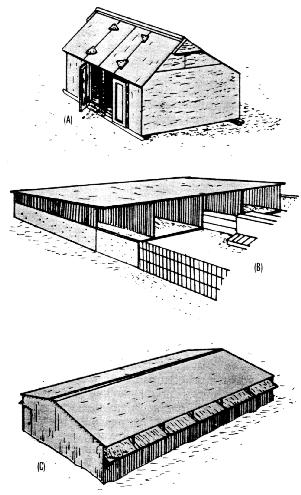

More specifically, natural ventilation is used primarily in three types of livestock buildings (Figure 1):

* Small housing units, such as calf hutches, individual farrowing houses and portable (often open-front) shelters for swine. Most allow the animal access to an outside exercise lot.

* Open-front buildings, either slotted floor type (usually for cattle above 700 pounds) or solid floor with heat or bedding and outside lot (for all sizes of cattle, sheep and hogs).

* Modified open-front buildings, so named because up to half of the area of both sidewalls can be opened in summer and closed in winter. Well-insulated modified open-front buildings are used for finishing and gestation swine, whereas lightly-insulated types are used for dairy, beef and sheep.

Natural ventilation methods date back to the first time animals were confined in shelters, when farmers left the barn door open to reduce moisture or heat buildup. Today's naturally-ventilated livestock shelters, although more sophisticated, operate on exactly the same principles.

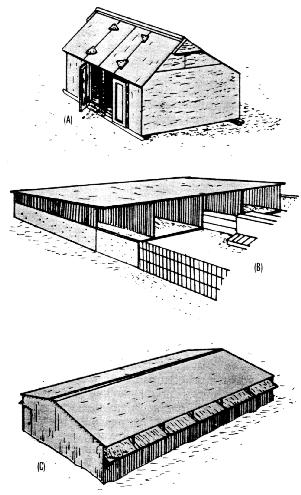

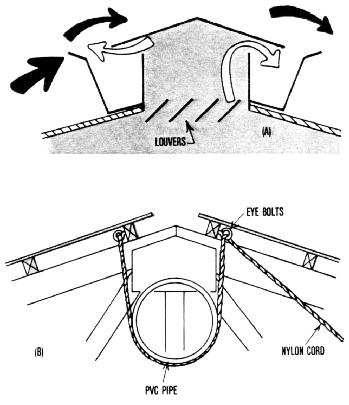

Natural ventilation occurs primarily because of the difference in wind pressure across a building, and to a lesser extent because of a difference in inside and outside temperature. A natural system works best in a building with no ceiling but having small openings at the eaves and ridge (peak) of the roof, and having large sidewall openings (Figure 2).

Winter ventilation occurs as wind blows across the open ridge of the gable-roof building. Suction is created which draws warm, moist air out of the building and fresh air in through the eave openings. If wind velocity is great enough, the downwind (leeward) eave openings can also act as air outlets.

On calm winter days, the hot, moist air still rises and eventually finds its way out the ridge opening. This chimney or `stack' effect accounts for only about 10 percent of the total ventilation, because there is not a great difference between inside and outside temperatures in most naturally-ventilated buildings, except on very cold days.

Summer ventilation is provided by opening up large portions (typically one-third to one-half) of each sidewall to allow a cross-flow of air, The ridge opening has little effect in summer.

Proper location of the building with respect to prevailing winds and surrounding trees, structures and land formations is essential to the success of a natural ventilation system. Locating on high ground is best, because it permits necessary drainage as well as exposing the building to the effects of wind.

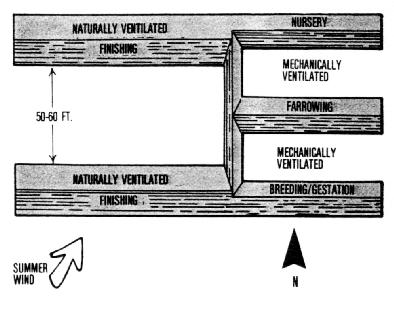

In Indiana, an open-front building is usually constructed with the long axis running east-west to maximize summer shade. Facing the open side to the south also minimizes the effect of the prevailing north and northwest winter winds.

A modified open-front swine unit is usually narrow enough that orientation has little effect on ventilation. Although solar heat load on the roof of a north-south oriented building is greater than that on an east-west oriented structure, modified open-front swine buildings are usually well enough insulated that this is not a major concern. However, a lightly-insulated modified type, such as dairy free-stall barns, should have its long axis running east-west to minimize the effect of the sun.

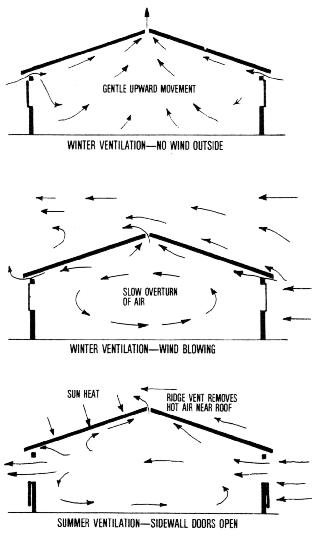

The presence of upright silos, grain bins, trees and other farm buildings can greatly affect air flow around a livestock shelter. Therefore, the question for the producer is, "How do I fit a naturally-ventilated building into my overall farmstead complex so as to insure adequate air flow?"

Figure 3 shows one solution to the problem. As a rule, naturally-ventilated units should be placed on the west or south side of the complex, with fan-ventilated units on the east or north.

When locating an individual naturally-ventilated building on the farmstead, try to place it upwind of other buildings or any obstructions that would block air flow. If it must be placed downwind, leave enough room to overcome the swirling effect caused by wind passing around and over the other building or obstruction.

To determine proper separation distances, use the following equation:

Dmin = 0.4h (L)1/2

where Dmin = the minimum distance needed (ft.)

h = building height at the ridge (ft.)

L = building length (ft.)

Example. Assume you must locate your new livestock shelter downwind from a building that is 28 feet by 96 feet by 13 feet high. How far apart should they be to maintain adequate natural ventilation?

Dmin = 0.4 X 13 X (96)1/2 = 5.2 X 9.8 = 51 feet

This is the minimum separation; a greater distance would be better. (For a more complete discussion on the effects and control of wind around the farmstead complex, see Purdue Extension Publication AE-102.)

Since the wind can be toward either side of the building, the intake or vent opening on each side should be at least as large as the ridge vent opening on top. Size of the vent openings can be determined using the equation:

4.7Q

A = -----

V

where A = area of vent inlet and/or outlet openings (sq.in.)

Q = ventilation rate (cfm)

V = wind velocity (mph)

Example. A swine producer wants to design winter ventilation on the basis of 10 cfm per finishing hog and a 10 mph wind velocity. What size should the ridge and each eave vent opening be?

4.7 x 10

A = -------- = 4.7 or about 5 sq.in. per hog

10

* Much of the design data tor natural ventilation presented here comes from studies by the Agricultural Engineering Department at the University of Illinois.

Inches of opening per 10 feet of building width

----------------------------------------------------------------

Summer sidewall openings**

Winter ridge ---------------------------------------------

& eave vent Gable roof, Monoslope, Monoslope,

Type housing openings* both walls back wall front wall

-----------------------------------------------------------------------------------

in./10 ft. width

Swine 0.5 14 7 21

Reef 2.0 9 5 15

Dairy 1.0 6 4 12

Sheep 0.25 6 4 12

-----------------------------------------------------------------------------------

* Sized to provide cold weather ventilation at 10 mph wind

velocity. Minimum ridge opening should be 4 inches wide to prevent

freezing.

** Gable-roof building openings sized to provide hot weather

ventilation at about 1 mph wind velocity. Monoslope-roof openings

modified to take advantage of the 'funneling' effect which increases

the velocity of incoming air in summer.

Table 1 shows proper vent opening sizes for winter and summer natural ventilation in housing for various types of livestock. These figures were arrived at using the above equation and current animal floor space recommendations for confinement buildings.

Let's assume that a 28- by 96-foot, gable-roofed finishing building houses 320 hogs. To determine the size of its winter vent openings (Table 1, column 2), multiply 0.5 inch (per 10 feet of building width) x 2.8 (10-foot units) 1.4 inches of vent opening width for the entire length of the building.

The ridge and eave opening values in column 2 are minimum sizes. If the eave and ridge vents have adjustable closures, they can be made 25-50 percent larger to provide improved ventilation on calm winter days.

But in order to prevent frost from forming at the point where the warm, moist air leaves the building, the ridge opening (or downwind eave opening in the case of a monoslope building) should be at least 4 inches wide. To do this and still maintain an equivalent ventilation area, open only the ridge in every third truss bay to a width of 4.2 inches (3 x 1.4 inches).

Our example building's summer ventilation sidewall openings should be at least the sizes shown in Table 1 in both sidewalls-i.e., a continuous opening of 14 inches per 10 feet of building width. Total vent size, therefore, is 14 inches x 2.8 (10-foot units) 39.2 inches for the length of the building. (In summer, the ridge vent is useful only to let out the hot air trapped in the ridge area.)

To allow for the portion of vent area obstructed by building framing and post supports, 42-inch-high vent doors should be used along both sidewalls to insure at least the equivalent of 39.2 inches. Even if one sidewall is completely open, as in an open-front building, the backwall vent opening still should not be made smaller than the value shown in Table 1.

The required vent widths shown in Table 1 are the minimum `free' (unobstructed) openings. Therefore, if using a commercial ridge ventilator with a screened opening, be sure to compensate for the reduced actual vent area by purchasing one that is at least 25 percent larger than needed.

Some commercial ridge ventilators have adjustable openings which can be closed as needed during severe weather (Figure 4). This is a useful option in buildings where freezing temperatures may harm animals and water supply lines.

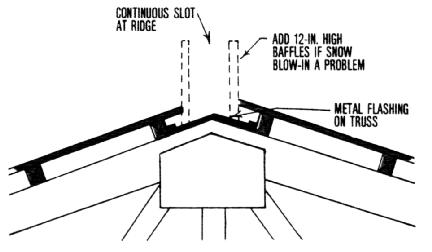

Cattle and sheep tolerate cold temperatures better than swine. Thus, ridge openings in housing units for these types of livestock can be constructed without the ridge cap, leaving the ridge completely open. In this case, be sure to protect the exposed truss area with flashing (Figure 5).

Many producers are concerned with snow blow-in around the ridge opening. Usually, an open ridge traps less snow than a raised ridge cap. However, if blow-in is a problem, vertical baffles placed along both sides of the open ridge will decrease blow-in and may even improve ventilation slightly (Figure 5).

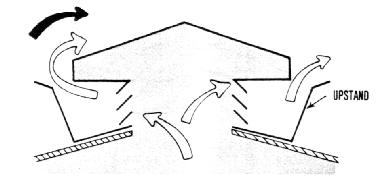

`Upstands' that deflect wind and snow up over the cap are available for some commercial ridge vents (Figure 6). However, regardless of the type of ridge vent used, snow blow-in will still occur at times when snow blows parallel to the ridge, since the downwind portion of the roof will be under pressure.

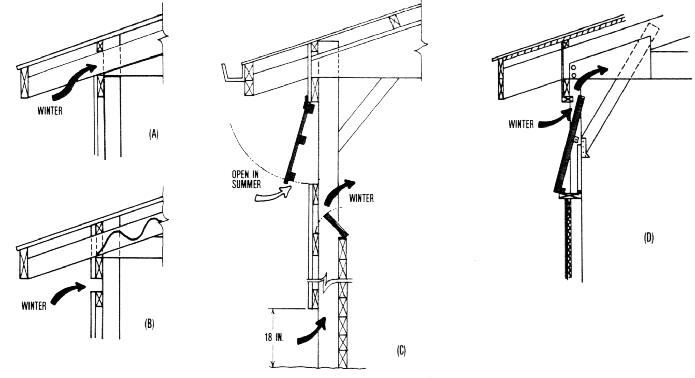

Eave vents (winter air inlets) can simply be the open spaces between the rafters or trusses at the top of the wall. This area is usually large enough to meet the eave opening requirement in Table 1 except in buildings over 40-50 feet. Buildings with insulated roof panels that obstruct the space between trusses must have other means for allowing adequate air to enter. Typical eave vents are shown in Figure 7.

Eave vents should always be protected against direct wind, which can create unwanted drafts in the animal area. Forcing air up through a hollow-wall vent or through a rafter or truss cavity protected by a large facia board, helps break up wind gusts. Also, bringing in winter air high on the sidewall allows it to warm up some before reaching animal level and improves air circulation in the building.

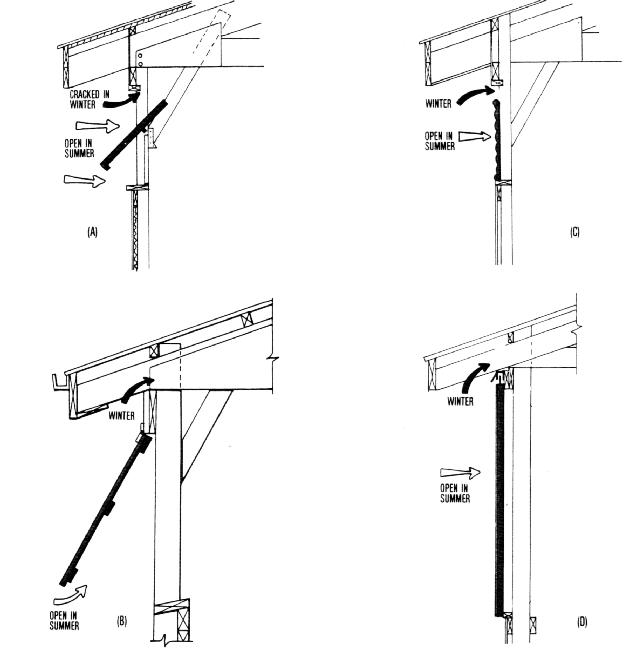

Several types of doors are being used satisfactorily for sidewall ventilation, including the pivot door, top- or bottom-opening door, sliding door and curtain (Figure 8). The curtain and the pivot or `butterfly' door are popular for swine buildings, since they can be adjusted easily with automatic controllers.

Giving attention to the following aspects of a natural ventilation system will help insure its effectiveness.

Roof slope is important to good ventilation. As a rule, the steeper the slope, the better the ventilation. If possible, avoid slopes less than 3/12 (3 inches of rise per foot of run). And generally, the wider the building, the steeper the roof slope should be.

Obstructions protruding from the underside of the roof, such as deep purlins, can trap moist air and increase metal corrosion and wood deterioration. Therefore, avoid wide truss spacings which require deep exposed purlins. Never use purlins deeper than 6 inches (4 inches preferred), if the building is to be ventilated naturally.

Sidewall height can also affect natural ventilation. For instance, if walls are not high enough, mechanical bunks can disrupt proper air flow through the building in summer. Also, winter sun cannot penetrate open-front buildings adequately if wall height is insufficient.

Wall height becomes more important as building width increases, if enough sidewall vent area is to be available for summer air flow. Table 2 shows the proper wall height-building width relationships in housing for beef and dairy.

Wall height when building width is -

-----------------------------------------------------------

40 ft.

Type housing or less 50 ft. 60 ft. 70 ft. 80 ft. 100 ft.

--------------------------------------------------------------------------

ft. of height

Beef 12 14 14 16 16 16

Dairy 8 8 10 10 12 12

--------------------------------------------------------------------------

Insulation prevents condensation as well as helping conserve animal heat. All livestock produce water vapor through waste production and respiration. A dairy cow, for example, respires the equivalent of 4-5 gallons of water per day. This water vapor rises and can condense if the air carrying it cools off enough. Insulation helps keep the roof surface warm enough to prevent condensation when moist air contacts it.

If a livestock building is operated as a cold building, such as an open-front unit, the temperature difference between inside and out is only about 5 degrees; therefore, condensation problems are minimal. In this case, insulation is of marginal benefit unless needed to reduce the solar heat load in summer.

If a building is mostly closed in winter, such as a total covered freestall barn, the difference between inside and outside temperature is around 20-30 degrees, and condensation may occur. A minimum amount of insulation (R-value of 4-5) placed beneath the roof will prevent the problem.

Modified open-front swine buildings should be maintained at temperatures above 45 F. An insulation level of R=13 is recommended for both the roof and sidewalls. (See Purdue Extension Publication AE-95 for details on adding insulation to livestock buildings.)

During periods of changing weather conditions, sidewall doors and ridge vent openings should probably be adjusted several times a day to avoid a sudden temperature change in the building. Eave vents are seldom closed except in the case of blowing snow. In some modified open-front buildings, sidewall doors are cracked open in winter instead of using eave openings. If this is done, flashing is needed at the bottom of the door to keep cold air from coming in there (Figure 7D).

Winter ventilation control is accomplished by closing the sidewall opening, ridge opening, or both.

To eliminate much of the worry associated with sudden temperature changes, many producers use automatic door controllers. Several types are available commercially. Most work much like overhead garage door openers, except that they operate in response to a thermostat instead of radio waves.

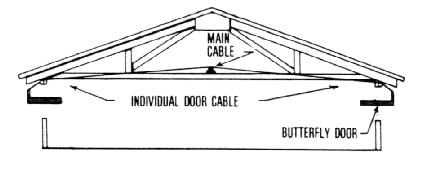

Generally, controllers are used with only plastic fabric curtains or butterfly doors, because they require less power to operate than bottom- or top-hinged doors.

Plastic curtains, being relatively lightweight, lend themselves well to automatic control. They fasten at the bottom and are raised or lowered from the top, using a system of cables and pulleys.

Butterfly doors are usually hinged just above their center to minimize the force on the controller, so they tend to be self-closing when pressure on the cable is released. If butterfly doors are to open completely to the horizontal position, the individual cables must be connected to arms located on the outside of the doors (Figure 9). The cables run up over the top of the doors and are connected through a pulley to the main cable attached to the controller.

Locate the controller in the center of the building, so equal force is exerted from both directions. This puts less strain on the controller supports than locating the unit at one end of the building and pulling all of the doors from only one direction.

If using automatic controllers, it is wise to have standby power units that will engage in case of power failure. One commercial model operates on a 12-volt battery. The battery remains plugged into a trickle charger, so several additional hours of ventilation control are possible if a power failure occurs.

Manual control of vent intakes usually means a wider fluctuation in building temperature but, of course, is less expensive. Make adjustment of doors as easy as possible to encourage continued proper regulation of openings. One suggestion would be winches located just inside the building entrance and connected to a system of cables and pulleys so that several doors can be opened at one time--similar to an automatic system.

Regardless of the system used, you must decide on both a desired temperature inside the building and a sequence for door opening. Referring again to our 28- by 96-foot, gable-roofed swine finishing building, an example natural ventilation system operating scheme might be as follows:

Open-front buildings as well as cold confined dairy housing usually have only limited ventilation control, so animals must be able to adjust to rapidly changing temperature conditions. Typically, summer vent doors in the back sidewall are opened in the spring and closed in the fall, with ridge vents seldom closed, regardless of weather conditions. This is in contrast to the modified open-front swine buildings, in which frequent ventilation adjustments are necessary in response to changing weather conditions.

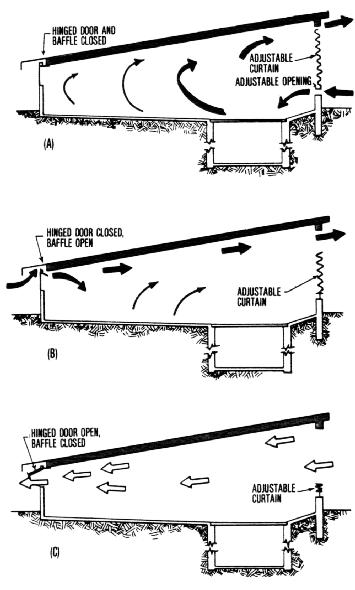

The main difference between a monoslope (entire roof slopes in one direction) and gable-roof building is that the monoslope has no center ridge opening to adjust. It is usually oriented with the high or open-front facing the south. Summer ventilation is accomplished using a cross-flow of air from one sidewall to the other, while winter ventilation is accomplished by air entry and discharge through openings in the highest wall (Figure 10).

Modified open-front monoslopes are operated for winter ventilation by adjusting the vent openings on the high sidewall (Figure 10A). When outside temperatures fall below 20 F, the low or back wall vents should be completely closed. Ventilation air enters through a bottom opening in the high wall. The cold air moves 10-15 feet back into the building, cooling the slat area, and rises as it is warmed by the body heat of the animals. The heated air then travels along the sloped roof and exits through an opening near the top of the high sidewall. All vent openings, including the bottom opening in the high sidewall, should be sized as recommended in Table 1.

As outside temperatures begin rising above 20F,the eave vents along the low sidewall should be opened (Figure 10B). In summer, the sidewall openings (sized according to Table 1) are opened to allow for a cross-flow of ventilation air (Figure 10C). (In Indiana, typically the low sidewall opening is a tilt door and the high sidewall opening is a plastic curtain.)

Open-front monoslopes are operated the same as conventional open-front gable-roof buildings. That is, the sidewall opening on the low (windward) side should be closed in winter and opened in summer according to the eave and sidewall recommendations in Table 1. In winter, ventilation air exits on the high (open-front) side instead of through a ridge opening.

The building should be oriented so that the high wall opening catches the prevailing summer breeze, while blocking out the prevailing winter wind. Then, since building height decreases as air nears the low sidewall, the `funneling' effect increases air velocity and thus aids in cooling. (In Indiana, the open-front usually faces south.)

In winter, as long as sufficient ventilation air moves through the building, poor air distribution is not generally a problem. But occasionally, draft conditions do occur, particularly in open-front buildings.

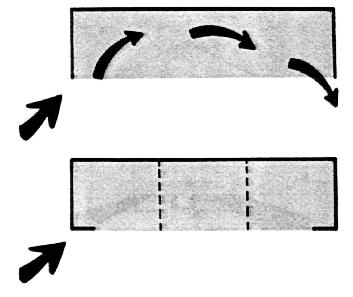

When the wind blows against an endwall of a naturally-ventilated building, air tends to enter at the upwind end and leave at the downwind end, creating drafts throughout the length of the building (Figure 11). In modified open-front buildings, these drafts can be broken up by making every other pen cross-partition solid (about 25 feet apart). In open-front buildings, cross-partitions should be as high as the sidewall opening and located at spacings of 2 1/2 times the building width (but no more than 80 feet apart).

In some open-front structures, it may be necessary to close off the feed alley along the back to stop drafts. Automatic garage doors are a good solution here, since they stop drafts but allow convenient movement of feed handling vehicles. Other drafts are caused by wind swirling around the ends or over the top of an open-front building. (Consult Purdue Extension Publication AE-102, regarding wind and snow control around the farmstead.)

Dead air zones or `hot spots' can be a summer ventilation problem in some buildings. Pen partitions running parallel to the length of the building should be open or `porous' to allow a cross-flow of air currents. Don't place a large feeder along the end of a pen where it would block air flow across the building.

It is doubtful whether using a porous partition as the lower part of the outside wall in a modified open-front swine building is effective, except for the animals just next to the opening. However, if such an opening is used, be sure to close it up in winter.

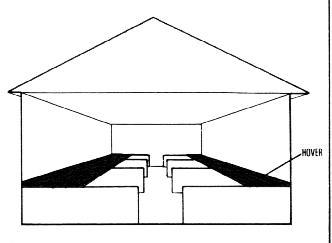

Buildings with high eave heights are more subject to drafts than low-profile buildings because of their larger volume. For example, cattle sheds or machinery storages remodeled for swine housing often have serious draft problems. And they are usually too large to heat the air enough to moderate any drafts. The only solution is either to drop the ceiling to 7-8 feet high and use mechanical means to ventilate, or to add plywood or polyethylene sheet hovers at the rear of the pens to provide sleeping areas where animals can move out of the draft (Figure 12).

A good recommendation for swine and other draft-susceptible animals is to limit building width to less than 35 feet, which in turn lowers the necessary eave height (see Table 2).

Natural ventilation offers a means of providing an environment conducive to efficient livestock production while not adding to the farmer's energy bill. In an era of rising fuel prices, the savings may be substantial.

Understanding why good ventilation is necessary and applying the principles of natural ventilation presented here can improve the performance of your livestock building. Finally, proper building location together with good ventilation system design, operation and maintenance can help ensure its success.

Single copies of the following "Energy Management in Agriculture" publications are available free to Indiana residents from their county Cooperative Extension Service office or by writing to Media Distribution Center, 301 S. 2nd St., Lafayette, IN 47901-1232:

"Environmental Control for Livestock Housing" (AE-96)

"Insulation of Livestock and Other Farm Buildings" (AE-95)

"Pit Ventilation Systems for Livestock Housing" (AE-98)

"Solar Heating Systems for Livestock Buildings" (AE-99)

"Swine Housing and Equipment Handbook" (MWPS-6)

"Troubleshooting Environmental Control Systems" (AE-100)

"Wind and Snow Control for the Farmstead" (AE-102)

New 7/80

Cooperative Extension work in Agriculture and Home Economics, state of Indiana, Purdue University, and U.S. Department of Agriculture cooperating; HA. Wadsworth, Director, West Lafayette. IN. Issued in furtherance of the acts of May 8 and June 30, 1914. Purdue University Cooperative Extension Service is an equal opportunity/equal access institution