NCR-135

All too often, exterior finishes for wood are short-lived in durability or fail completely. Failure is usually the result of the wrong kind of finish being applied to the wood surface or of not following recommended application procedures. In either case, the homeowner is faced with the expensive and time consuming problem of refinishing. Instruction should be given in selecting the appropriate finish/wood combination and in following through by applying the finish as specified by the manufacturer. This publication will discuss how to select the appropriate finish for the many different types of wood products currently used on structures as well as correct application procedures.

There are three general categories of wood products commonly used in construction. These are (1) lumber, (2) plywood, and (3) reconstituted wood products, such as hard board and particleboard. Each product has unique characteristics which will affect the durability of any finish applied to it.

Lumber is being used less and less as exterior siding, but was once the most common wood material used in construction. Many older homes have wood siding. The ability of lumber to retain and hold a finish is affected by species, by grain direction or how the piece was sawn, and by smoothness.

The weight of wood varies tremendously between species. Some common construction woods such as southern yellow pine are dense and heavy with respect to the lighter weight ones such as redwood and cedar. The weight of wood is important because heavy woods shrink and swell more than light ones. This dimensional change in lumber occurs as the wood gains or loses moisture. Wood in heated homes tends to dry and shrink in the winter and gains moisture and swells in the warm summer months. Excessive dimensional change in wood consistently stresses a paint film and may result in early failure.

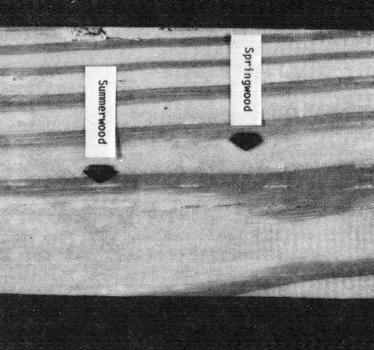

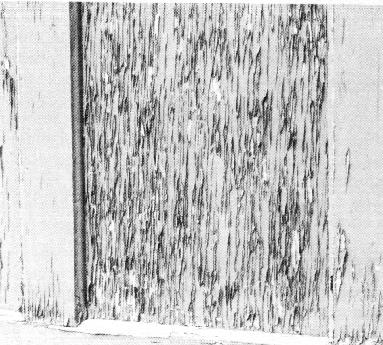

Some species have wide bands of dark, dense wood alternating with bands of light, softer wood. The light bands are formed in the spring of the year and are called springwood or earlywood. The dark bands are formed in the summer and are called summerwood or latewood (Figure 1). Bands of summerwood are characteristic of southern yellow pine and some boards of Douglas-fir. Paint will not hold well on these species, and penetrating stains are preferred. On the other hand, wide summerwood bands are not characteristic of redwood and cedar; therefore, these species are preferred when paint will be used.

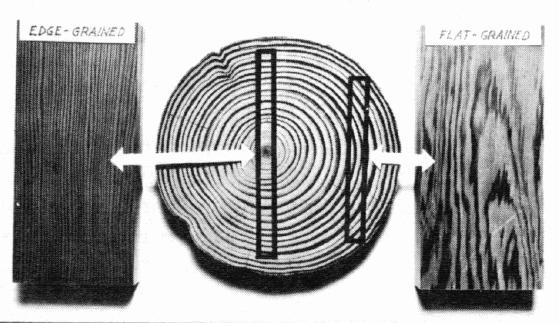

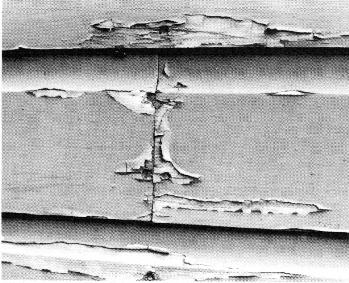

Grain direction also affects paint-holding characteristics and is determined at the time lumber is cut from a log. Lumber is referred to as flat-grained, edge-grained (quartersawed) or a combination of the two (Figure 2). Most standard lumber contains a high percentage of flat grain. Lumber used for board and batten siding, drop-siding or shiplap is frequently flat-grained. Bevel siding of redwood or cedar is often, but not always, manufactured so that it is edge-grained. Edge-grained bevel siding will hold paint well. Flat-grained lumber will not hold paint as well since it shrinks and swells more than edge-grained lumber and because wide, dark bands of summerwood are frequently present (Figure 3).

Paint will last longer on smooth, edge-grained surfaces. Penetrating stains or preservative treatments are preferred for rough sawn lumber. These treatments often accentuate the natural or rustic look of rough sawn lumber and allow the wood grain and surface texture to show through the finish.

Exterior plywood with a rough sawn surface is commonly used for siding. Smooth sanded plywood is not recommended for siding, but it may be used in soffits. Sanded and rough sawn plywood will develop surface checks, especially when exposed to moisture and sunlight. These surface checks can lead to early paint failure with oil or alkyd paint systems (Figure 4). Quality acrylic latex paint systems generally perform better. The flat-grained pattern present in nearly all plywood can also contribute to early paint failure. Therefore, if smooth or rough sawn plywood is to be painted, special precautions should be exercised. Penetrating stains are often more appropriate for both smooth sanded and especially rough sawn exterior plywood surfaces.

Plywood manufactured with a medium density paper overlay is frequently called MDO. Compared to standard rough sawn or smooth plywood, MDO holds paint well. MDO plywood is not always a stock item in many lumber yards, but it can usually be ordered.

Reconstituted wood products are those made by forming small pieces of wood into large sheets usually 4 by 8 feet or as required for a specialized use such as beveled drop siding. These products may be classified as fiberboard or particleboard, depending upon the nature of the basic wood component.

Fiberboards are produced from mechanical pulps. Hard board is a relatively heavy type of fiberboard and is used for exterior siding. It is often sold in 4 by 8 foot sheets and as a substitute for beveled drop siding, traditionally made from solid wood.

Particleboards are manufactured from whole wood in the form of splinters, chips, flakes or shavings. Waferboard and flakeboard are two types of particleboard made from relatively large flakes or shavings.

Only some fiberboards and particleboards are manufactured for exterior use. Film-forming finishes such as paints and solid color stains will give the most protection to these reconstituted wood products. Some reconstituted wood products may be factory primed with paint, and some may even have a top coat.

Paints are common coatings used on wood and provide the most protection. They come in a wide range of colors and may be either oil or latex based. Latex-based paints and stains are water borne, and oil or alkyd paints are solvent borne. Paints are used for aesthetic purposes, to protect the wood surface from weathering and to conceal certain defects.

Paints are applied to the wood surface and do not penetrate it deeply. The wood grain is completely obscured, and a surface film is formed. This surface film can blister or peel if the wood is wetted or if inside water vapor moves through the house wall and wood siding because of the absence of a vapor barrier.

Latex paints are generally easier to use since water is used in clean-up. They are also porous and, thus, will allow some moisture movement. In comparison, oil-based paints require organic solvents for clean-up, and some are resistant to moisture movement.

Paints perform best on smooth, edge-grained lumber of lightweight species such as redwood and cedar. Paints are the only way to achieve a bright white finish. However, they are subject to peeling where moisture is a problem.

Solid color stains, also called heavy bodied stains, are opaque finishes which come in a wide range of colors and are defined as stains. Solid color stains are made with a much higher concentration of pigment than the semitransparent penetrating stains. As a result they will obscure the natural wood color and grain. Oil-based solid color stains tend to form a film much like paint and as a result can also peel loose from the substrate. Latex-based solid color stains are also available and form a film as do the oil-based solid color stains. These stains are similar to thinned paints.

Semitransparent penetrating stains are growing in popularity. They are moderately pigmented and, thus, do not totally hide the wood grain. These stains penetrate the wood surface, are porous, and do not form a surface film like paints. As a result, they will not blister or peel even if moisture gets into the wood. Penetrating stains are alkyd or oil-based, and some may contain a fungicide or water repellent. Latex-based (water borne) stains are also available, but they do not penetrate the wood surface as do the oil-based stains.

Stains are most effective on rough lumber or plywood surfaces, but they also provide satisfactory performance on smooth surfaces. They are available in a variety of colors and are especially popular in the brown tones since they give a "natural or rustic wood appearance." They are not available in white. They are also an excellent finish for weathered wood. They are not effective when applied over a solid color stain or over old paint.

A water-repellent preservative may be used as a natural finish for wood surfaces. It contains a wood preservative, a small amount of wax as a water repellent, a resin or drying oil, and a solvent such as turpentine or mineral spirits. Water-repellent preservatives do not contain any coloring pigments. Therefore, the resulting finish will vary in color depending upon the kind of wood. The preservative prevents wood from graying by inhibiting mildew.

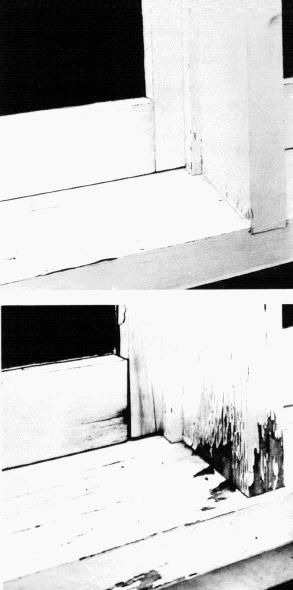

Water-repellent preservatives may also be used as a treatment for bare wood before priming and painting or in areas where old paint has peeled, exposing bare wood, particularly around butt joints or in corners. This treatment keeps rain or dew from penetrating into the wood, especially at joints and end grain, and thus decreases the shrinking and swelling of wood. As a result, less stress is placed on the paint film, and its service life is extended (Figure 5). This stability is achieved by the small amount of wax present in water-repellent preservatives. The wax also decreases the capillary movement of water up the back side of lap or drop siding. The fungicide inhibits surface decay.

Be sure to purchase the correct type of water-repellent preservative. Any type of water-repellent preservative can be used as a natural exterior finish by itself, but only some are paintable. Manufacturers have also developed water-repellent preservatives specifically for exterior finishes.

Water repellents are also available. These are simply water-repellent preservatives with the preservative left out. Water repellents are not good natural finishes but can be used as a stabilizing treatment before priming and painting.

Before purchasing and using a water-repellent preservative or water repellent, read the label carefully and follow the manufacturer's directions.

Varnishes, synthetic resins and other clear film-forming finishes provide an attractive finish for wood since they allow the natural wood color and grain to show through. Unfortunately, the durability of these finishes on wood under the action of sunlight and moisture is limited. Regardless of the number of coats applied, the film will begin to crack and peel, and the finish will have to be completely removed by sanding or with a varnish remover before a new coat is added. In severe exposures, clear film finishes may last barely one year. Alternate finishes such as semitransparent stains and water-repellent preservatives will give a longer service life and are easier to refinish.

Exterior marine or spar varnishes may be used with some success on exterior doors and other areas if adequate protection from the weather is provided.

Wood preservatives are not considered to be finishes. However, wood properly treated with a preservative can withstand years of exposure to severe decay and insect attack without being affected. The common wood preservatives are creosote, pentachlorophenol in oil, and the newer water-borne salt treatments-all of which are restricted-use pesticides (see Warning on back page). Creosote and pentachlorophenol in oil result in a dark and oily surface. Odor with creosote is a problem. Wood treated with creosote or pentachlorophenol in oil is not recommended for use around the home where people will come in contact with it. However, wood treated with water-borne salts is suggested for use as patio decks, outside steps, privacy fences and other home uses. This material is generally light to bright green or brown in color. It can be used outdoors without finishing and will go practically unchanged or weather to a light gray.

Proper surface care and preparation before applying paint to wood is essential for good performance. Wood and wood-based products should be protected from the weather and wetting on the job site and after they are installed. Surface contamination from dirt, oil and other foreign substances must be eliminated. It is best to paint wood surfaces within 2 weeks, weather permitting, after installation.

To achieve maximum paint life, follow these steps:

To avoid future separation between paint coats, the first top coat should be applied within 2 weeks after the primer and the second coat within 2 weeks of the first. As certain paints weather they can form a soap-like substance on their surface which may prevent proper adhesion of new paint coats. If more than 2 weeks elapse before applying another paint coat, scrub the old surface with water using a bristle brush or sponge. If necessary, to remove all dirt and deteriorated paint, use a mild detergent. Then rinse well with water, and allow the surface to dry before painting.

To avoid temperature blistering, oil-base paints should not be applied on a cool surface that will be heated by the sun within a few hours. Temperature blistering is most common with thick paint coats of dark colors applied in cool weather. The blisters usually show up in the last coat of paint and occur within a few hours to 1 or 2 days after painting. They do not contain water.

Oil-base paint may be applied when the temperature is 40°F or above. A minimum of 50°F is desired for applying latex-based paints. For proper curing of the paint film, the temperature should not drop below 50°F for at least 2 hours after paint application. Low temperatures will result in paint failure.

To avoid wrinkling, fading or loss of gloss of oil-base paints and streaking of latex paints, the paint should not be applied in the evenings of cool spring and fall days when heavy dews form before the surface of the paint has thoroughly dried.

Solid color stains may be applied to a smooth surface by brush or roller application, but brush application is best. These stains act much like paint. One coat of solid color stain is adequate, but two coats will provide better protection and longer service.

Unlike paint, lap marks may form with a solid color stain. Latex-based stains are fast-drying and are more likely to show lap marks than the oil-based ones. To prevent lap marks follow the procedures suggested under application of semitransparent penetrating stains.

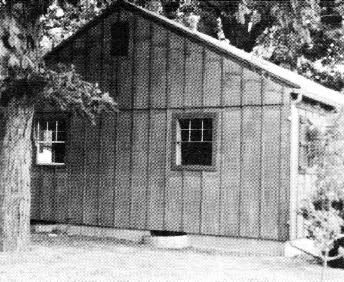

Semitransparent penetrating stains may be brushed or rolled on. Brushing will give better penetration and performance. These stains are generally thin and runny, so application can be messy. Lap marks will form if stains are improperly applied (Figure 7). Lap marks can be prevented by staining only a small number of boards or a panel at one time. This method prevents the front edge of the stained area from drying out before a logical stopping place is reached. Working in the shade is desirable because the drying rate is slower. One gallon will usually cover about 300-400 square feet of smooth surface and from 150-200 square feet of rough surface.

For long life with penetrating oil-base stain on rough sawn or weathered lumber, use two coats and apply the second coat before the first is dry. Apply the first coat to a panel or area as you would to prevent lap marks. Then work on another area so that the first coat can soak into the wood for 20 to 60 minutes. Apply the second coat before the first coat has dried. (If the first coat dries completely, it will seal the wood surface so that the second coat cannot penetrate into the wood.) About an hour after applying the second coat, use a cloth or sponge to wipe off the excess stain that has not penetrated into the wood. Stain which did not penetrate will form an unsightly surface film and glossy spots. Avoid intermixing different brands or batches of stain. Stir stain thoroughly during application. Note: Sponges or cloths that are wet with oil-base stain are particularly susceptible to spontaneous combustion. To prevent fires, bury them, immerse them in water, or seal them in an airtight container immediately after use.

A two-coat wet system on rough wood may last as long as 10 years in certain exposures. If only one coat of penetrating stain is used on new wood, its expected life is 2 to 4 years, but succeeding coats will last longer.

The most effective method of applying a water-repellent preservative is to dip the entire board into the solution. However, brush treatment is also effective. When wood is treated in place, liberal amounts of the solution should be applied to all lap and butt joints, edges and ends of boards and panels. It is important to apply liberal amounts of the solution to the end grain of wood. Areas especially vulnerable to moisture, such as the bottoms of doors and window frames, should not be overlooked. One gallon will cover about 250 square feet of smooth surface or 150 square feet of rough surface. The life expectancy is only 1-2 years, depending upon the wood and exposure. Treatments on rough surfaces are generally longer-lived than those on smooth surfaces. Repeated brush treatment to the point of refusal will enhance durability and performance.

If you are refinishing an old paint coat, proper surface preparation is essential if the new coat is to give the expected performance. First, scrape away all loose paint. Use sandpaper on any remaining paint to "feather" the edges smooth with the bare wood. Then scrub any remaining old paint with a brush or sponge and water. Rinse the scrubbed surface with clean water. Wipe the surface with your hand. If the surface is still dirty or chalky, scrub it again using a detergent. Mildew should be removed with a dilute household bleach solution. Rinse the cleaned surface thoroughly with fresh water and allow it to dry before repainting. Areas of exposed wood should be treated with a water-repellent preservative, or water repellent, and allowed to dry for at least two days, and then primed. Top coats can then be applied.

It is particularly important to clean areas protected from sun and rain such as porches and side walls protected by overhangs. These areas tend to collect water soluble materials that interfere with adhesion of the new paint. It is probably adequate to repaint these protected areas every other time the house is painted.

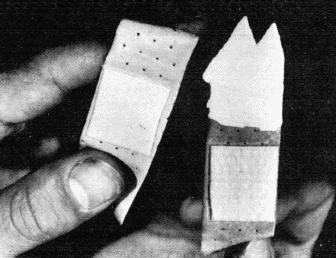

Latex paint can be applied over freshly primed surfaces and on some surfaces where an oil-base paint has already been used and weathered. Where old surfaces are to be repainted with latex paint a simple test should be conducted first. After cleaning the surface, repaint a small, inconspicuous area with latex paint, and allow it to dry at least overnight. Then, to test for adhesion, firmly press one end of a "band aid type adhesive bandage onto the painted surface. Jerk it off with a snapping action. If the tape is free of paint, it tells you that the latex paint is well bonded and that the old surface does not need priming or additional cleaning (Figure 8). If the new latex paint adheres to the tape, the old surface is too chalky and needs more cleaning or the use of an oil-base primer.

The same technique used to restore a paint coat can be used for solid color stains.

Semitransparent penetrating stains are relatively easy to refinish. Excessive scraping and sanding are not required. Simply use a stiff bristle brush to remove all surface dirt, dust, and loose wood fibers, and then apply a new coat of stain. The second coat of penetrating stain often lasts longer since it penetrates into small surface checks which open up as wood weathers.

Water-repellent preservatives can be renewed by a simple cleaning of the old surface with a bristle brush and an application of a new coat of finish. To determine if a water-repellent preservative has lost its effectiveness, splash a small quantity of water against the wood surface. If the water beads up and runs off the surface, the treatment is still effective. If the water soaks in, the wood needs to be refinished. Refinishing is also required when the wood surface shows signs of graying.

Note: Steel wool and wire brushes should not be used to clean surfaces to be finished with semitransparent stains or water-repellent preservatives since small iron deposits may be left behind. Pentachlorophenol may cause iron remaining on the surface to corrode. The corrosion products may then react with certain wood extractives to form a dark-blue, unsightly discoloration which becomes sealed beneath the new finishing system. Pentachlorophenol was commonly used in some semitransparent penetrating stains and water-repellent preservatives before it became a restricted-use pesticide.

The following are available from the Forest Products Laboratory, One Gifford Pinchot Drive, Madison, WI 53705-2398:

The following are available from the state Extension Services listed at the end of this publication:

"Finishing Exterior Plywood, Hardboard, and Particleboard." NCRExtension 132, revised 1988, 6 pp.

"Paint Failure Problems and Their Cure." NCR Extension Publication133, revised 1988, 6 pp.

"Discoloration of House Paint Causes and Cures." NCR ExtensionPublication 134, revised 1988, 6 pp.

"Finishing and Maintaining Wood Floors." NCR Extension Publication136, revised 1988, 8 pp.

The following is available from the Superintendent of Documents, U.S. Government Printing Office, 710 North Capitol Street, Washington, DC 20402 (order by title and stock number):

Slide/Tape Presentation

Acknowledgment is given to the Forest Products Laboratory. Forest Service. U.S. Department of Agriculture, Madison, Wisconsin for financial assistance in support of the preparation of this publication.

Do not mix bleach with ammonia or with any detergents or cleansers containing ammonia! Mixed together the two are a lethal combination, similar to mustard gas. In several instances people have died from breathing the fumes from such a mixture. Many household cleaners contain ammonia, so be extremely careful with what types of cleaners you mix bleach.

Use caution with wood finishes which contain pesticides. When used improperly they can be injurious to man, animals and plants. For safe and effective usage, follow the directions, and heed all precautions on the labels. It is advisable to wear unlined protective gloves and to cover nearby plant life when using any material containing pesticides.

Avoid spraying a pesticide wherever possible. Drift from a pesticide, applied as a spray, may contaminate the surrounding environment.

Store finishes containing pesticides in original containers under lock and key--out of reach of children and pets--and away from foodstuffs. Follow recommended practices for the disposal of surplus finishing materials and containers.

Note: Registrations of pesticides are under constant review by the Environmental Protection Agency and the Department of Agriculture. Use only pesticides that bear a Federal registration number and carry directions for home and garden use. Since the registration of pesticides is under constant review by State and Federal authorities, you should consult with a responsible State agency as to the current status of the pesticides discussed in this report.

Wood preservative warning. Because the preservatives creosote, pentachlorophenol, and water-borne salt treatments are restricted-use pesticides, only the wood treated with these materials may be sold to the general public. Suppliers of such treated lumber can provide EPA-approved consumer information sheets on its proper use and handling. Other preservatives classified as general-use pesticides are available to the public.

Rev 3/86

Sponsored by the Cooperative Extension Services of Illinois, Indiana, Iowa, Kansas, Michigan, Minnesota, Missouri., Nebraska, North Dakota, Ohio, South Dakota, Wisconsin, and Lincoln University-Missouri. Printed and distributed in cooperation with Extension Service, U.S. Department of Agriculture, Washington, D.C.

Programs and activities of the Cooperative Extension Service are available to all potential clientele without regard to race, color, sex, age, national origin, or handicap.

In cooperation with the North Central Region Educational Materials Project.

Issued in furtherance of Cooperative Extension work, Acts of Congress of May B and June 30, 1914, in cooperation with the U.S. Department of Agriculture and Cooperative Extension Services of Illinois, Iowa, Kansas, Michigan, Minnesota, Missouri Nebraska, North Dakota, Ohio, South Dakota, and Wisconsin. H.A. Wadsworth, Director Purdue University Cooperative Extension Service, West Lafayette, IN 47907.